Central control

All elements of the PROVENT ventilation system, from fans and control elements to kitchen hoods, are connected to one control cabinet. This brings you all the benefits of central control while simplifying the electrical installations.

A universal solution for all kitchens

The control cabinet has a high-performance controller with the same control programme in their control cabinets. This uniformity of the program ensures highly dependable operation and quick repair servicing. The program is modular and covers every combination of air extraction and supply for every commercial kitchen.

The best work conditions possible

The KIVENTIS control system automatically adjusts the extraction of air for each kitchen hood to the current activity of the thermal elements, ensures the required temperature conditions for work, optimises the ventilation of the area and reduces the draft as far as possible.

All information within reach

The ventilation system is highly automated, which means that there is no need for the manual control of operation and all the attention can be focused on cooking. However, the system can be easily controlled via the touch screen panel. The control panel mostly serves as a display of the state of the system and informs you when cleaning or repair services are needed. It also serves as a diagnostic tool for possible faults, which simplifies the repair services.

Remote control and diagnostics

The KIVENTIS control system can be connected to our service centre, which enables remote notification and the control of the ventilation system. This means that we can remotely spot the need for any preventive services, optimise the operation of the system and troubleshoot possible problems.

Compatibility with previous systems

One advantage of the KIVENTIS control system is that we pay a lot of attention to its compatibility with older ventilation systems during the design phase. This improves the safety of your investment and keeps down the costs of any updates you decide on.

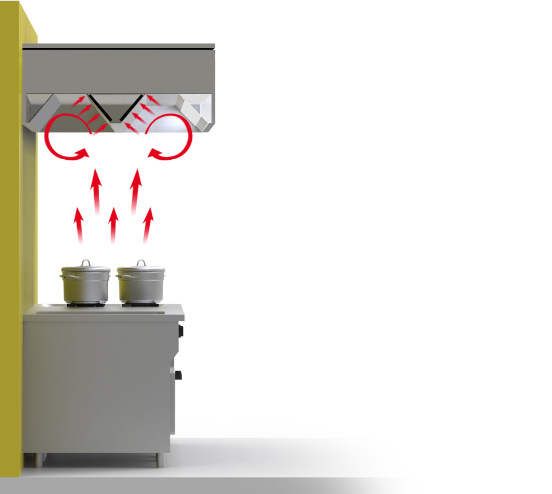

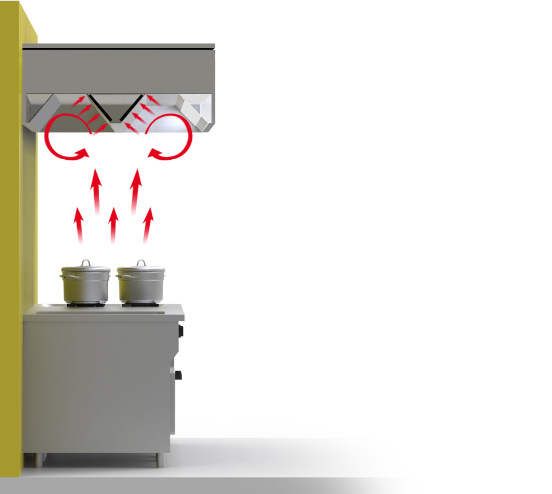

Patented extraction of exhaust air

The MEDIA highly efficient hood has a patented construction of the extraction area with filters under the hood, ensuring the efficient extraction of the exhaust air beneath the hood using up to 30 % less air volume. The costs of fan operation and air heating during the heating season are thus comparably lower.

Excellent ventilation, minimal draft

MEDIA achieves very even ventilation of the area around the hood by blowing fresh air through the slots in the entire upper circumference of the hood. The slots are adjustable to provide the best reach and volume of air. The work area in front of the cooking elements is additionally and more intensely ventilated by the fresh air that blows through the perforated front of the hood.

Fresh air for the entire kitchen

Thanks to the duct connectors at the top of the MEDIA highly efficient hood, fresh air can be distributed from the main space to other areas of the kitchen. This enables full ventilation in the food preparation area, dish-washing area and all other parts of the kitchen.

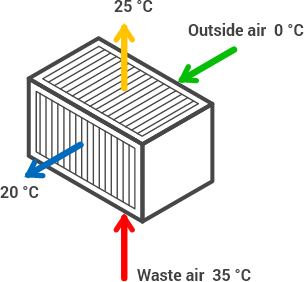

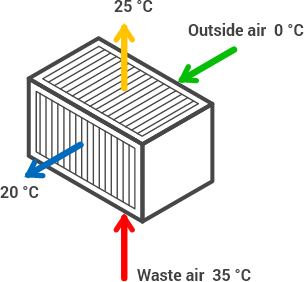

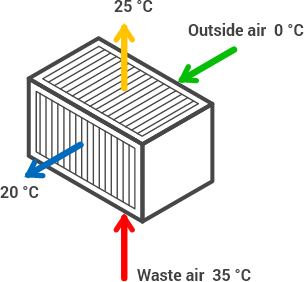

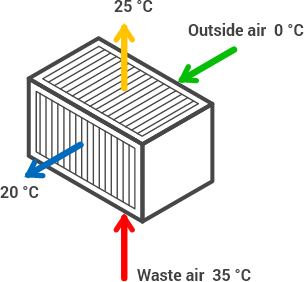

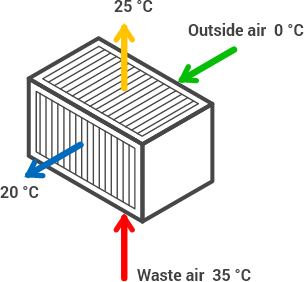

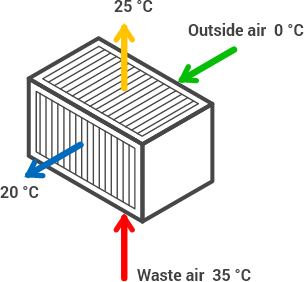

The economical heating of fresh air

The MEDIA highly efficient hood can heat up fresh air using the thermal energy of the exhaust air. When the air temperature under the hood reaches around 30°C, the fresh air during the heating season can be heated from 0°C to around 19°C without any additional heat source. Behind the plate heat exchanger, the hood also has a water heater, which provides additional warming of the incoming air as needed. The small plate heat exchangers built into the MEDIA hood also serve as the third phase of air filtration.

Very efficient air filtration

The highly efficient hood MEDIA has an inbuilt three-phase air filtration system: labyrinth filters, knitted mesh filters and plate heat exchangers. This is one of the most efficient mechanical filtration systems, which removes practically 100% of all grease particles sized 7 micrometres or larger (this is 11 times smaller than the width of a human hair), as measured by a certified DMT institute in Germany.

Lower cleaning costs

The cleaning costs of a ventilation system with the highly efficient hood MEDIA are lower compared to other heat recovery systems. All filters, including the plate heat exchangers, can be washed in the dishwasher, which allows the kitchen staff to do most of the washing and cleaning. The plate heat exchangers can be washed by any dishwasher in a commercial kitchen.

Lower maintenance costs

The maintenance costs of a ventilation system with the highly efficient hood MEDIA are lower compared to other heat recovery systems. The extremely efficient air filtration prolongs the period before the cleaning of the ducts and the exhaust fan. As the hood has an inbuilt heat recovery system, you do not need a heat recovery ventilation device with complex filters, which can be expensive and difficult to maintain.

Fresh air through the front side

The fresh air coming through the perforated front of the CONVECTA hood ensures excellent ventilation of the area in front of convection ovens. At the same time, it prevents the exhaust air escaping towards the ceiling when the oven doors are opened, as it quickly extracts it into the hood.

Efficient capture volume

The large capture volume under the CONVECTA hood serves as a sort of container that allows the hood to operate with a lower airflow than would otherwise be needed during the opening of the oven doors, when a large volume of steam and exhaust air is created in a short amount of time.

The economical heating of fresh air

The temperature of the air pulled in above convection ovens is often higher than 30°C. During the heating season, the small plate heat exchangers built into the hood can heat up the incoming air to the desired temperature. The CONVECTA hood has no inbuilt water heating for the additional heating of incoming air, as the MEDIA hood has. The regulation system automatically adjusts the volumes of the extracted and incoming air to the circumstances, ensuring that the air coming from the hood is always at the set temperature.

Two phase filtration of the exhaust air

The CONVECTA highly efficient hood has an inbuilt two-phase air filtration system: knitted mesh filters and plate heat exchangers, which perform a filtering function in addition to heat recovery. The filtration system is built into the front part of this wall-mounted hood, which increases the extraction efficiency when the convection oven doors are opened.

When should you choose the EXTRACTA hood?

The EXTRACTA exhaust hood is ideal when energy-saving hoods with heat recovery are not economically viable, usually due to the smaller airflow or less intensive operation of thermal elements. The EXTRACTA hood works in combination with the MEDIA highly efficient hood as the control system compensates for the air extracted through the EXTRACTA hood by supplying more fresh air through the MEDIA highly efficient hood.

Energy-saving

The airflow through the EXTRACTA exhaust hood is always adjusted to the intensity of the cooking, which saves energy. It also saves more than 50 % of the thermal energy needed for heating the air and of the electrical energy needed for the operation of the fans.

One- or two-phase filtration

The EXTRACTA hood above thermal cooking elements always has a two-phase air filtration system – labyrinth filters and knitted mesh filters. The EXTRACTA hood above a dishwasher only has the labyrinth filters.

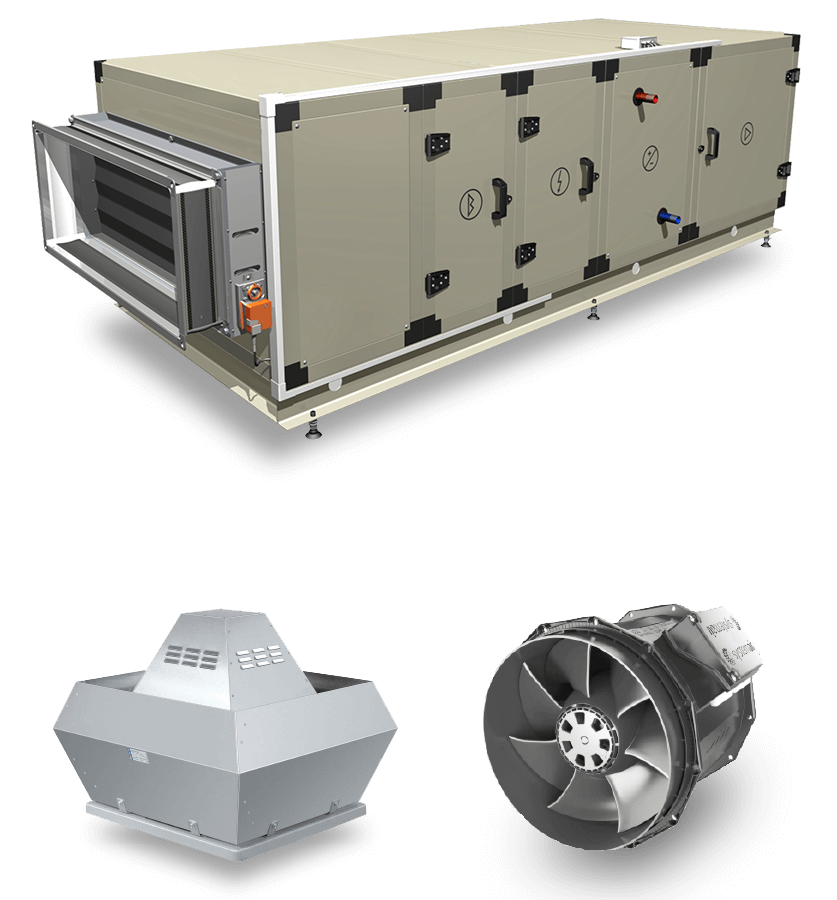

Ventilation devices

Exhaust fan

The exhaust fan can be either a rooftop device or a fan box. The electric motor, which can be EC or frequency-controlled, is always separated from the airflow. Several kitchen hoods can share one fan or every hood can have its own fan. A damper with the motor drive has to be built in with the fan. A silencer can be added if needed.

Supply ventilation device

This device is used to supply air into the energy-saving hoods with inbuilt plate heat exchangers. It can be internal or external. A damper with the motor drive, M5 pre-filter, F7 main filter and a glycol register or a register for the direct expansion of the refrigerant gas are always built in with the fan. A silencer can be added if needed.

Supply and extraction ventilation device

A supply and extraction ventilation device is always combined with plate heat exchangers. It is used in larger kitchens to supply and extract the air above thermal elements where there is no grease or other particles (dishwashing, the baking of bread and desserts …) and to ventilate other areas with special technologies.

Other devices

Cooling devices

During the summer, air cooling is essential for an efficient commercial kitchen. The KIVENTIS system can use three basic cooling systems:

- The use of cold water from a shared system for the entire object.

The cooling register of the supply device must be filled with a mixture of water and glycol to prevent the liquid freezing in the winter. - Air-to-water heat pump

The heat pump must be filled with a mixture of water and glycol. During the winter, the heating medium goes into the heating register in the energy-saving hood and in the summer the cooling medium goes into the cooling register in the supply ventilation device. - A direct expansion cooling device

A DX cooling device is connected to the cooling register in the supply ventilation device.

Control elements

The control part of the ventilation system includes various control elements and sensors – control dampers, air flow controllers, temperature sensors, pressure sensors and others.

OKSIAIR system for neutralisation of

the odour in exhaust air

Smells emitted from the kitchen into the environment are becoming a greater and greater problem in urban centres. To neutralise these odours, the OKSIAIR system with an exhaust air oxidation device can be built into the PROVENT ventilation system. The oxidation device also breaks down grease particles, which further minimises the dirtiness of the exhaust duct and fan.